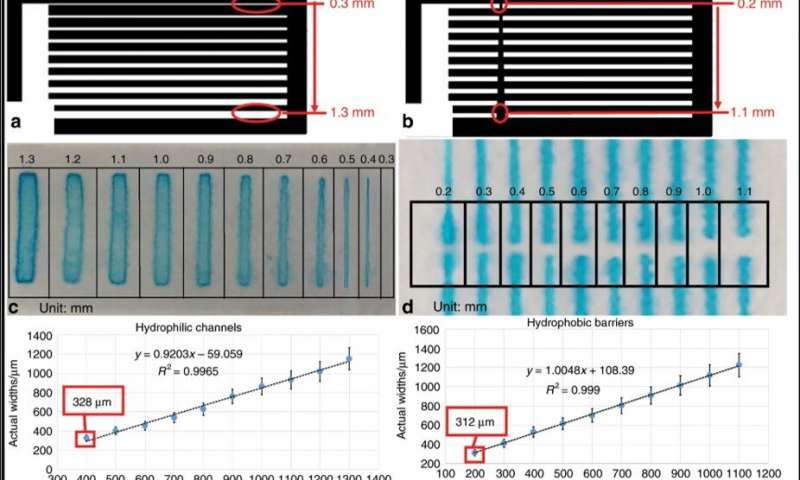

Microfluidic paper-based analytical devices (µPADs)

are a promising concept with rapid development in recent years. In

a new study published on Nature: Microsystems &

Nanoengineering, a team led by Yanfang Guan and Baichuan Sun in

electromechanical engineering in China, developed a new technique

to engineer µPADs known as atom stamp printing (ASP). The method

was cost-effective, easy to operate and allowed high production

efficiency with high resolution. As a proof of concept, they used

µPADs engineered via the ASP method to detect varied concentrations

of copper (Cu2+) via a colorimetric method. The devices achieved a

Cu2+ detection limit of 1 mg/L. Guan et al. also created a new

paper-based solid-liquid extraction device (PSED) using a

three-dimensional (3-D) µPAD with a “3+2” structure and recyclable

extraction mode. Due to the characteristics of paper filtration and

capillary force, the device could efficiently complete multiple

extraction and filtration steps from solid-liquid extraction

processes. The PSED platform allowed simple, cost-effective and

fast heavy metal ion detection at point-of-care. The work has great

promise for applications in food safety and environmental pollution

in resource-limited areas.

Heavy metal ion detection and extraction using paper-based

atom stamp printed devices