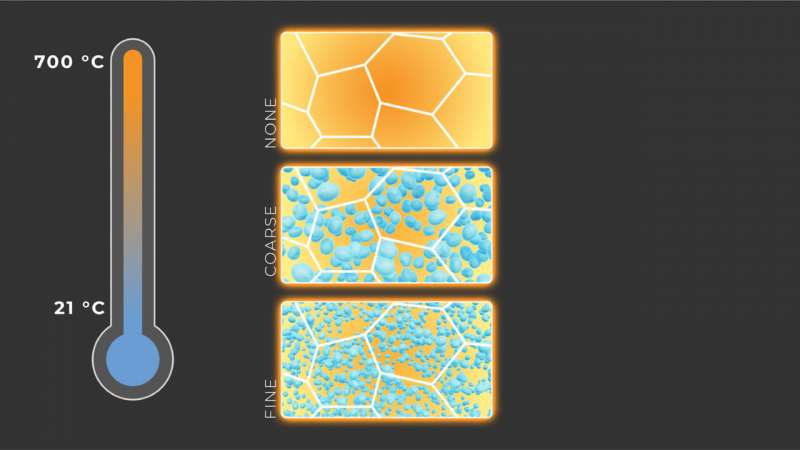

Scientists at the Department of Energy’s Oak Ridge

National Laboratory and the University of Tennessee, Knoxville,

have found a way to simultaneously increase the strength and

ductility of an alloy by introducing tiny precipitates into its

matrix and tuning their size and spacing. The precipitates are

solids that separate from the metal mixture as the alloy cools. The

results, published in the journal Nature, will open new avenues for

advancing structural materials.