Magnetically responsive microtextured surfaces have

the advantage of being controlled remotely (i.e., no contact is

required) at ambient conditions and short response times.

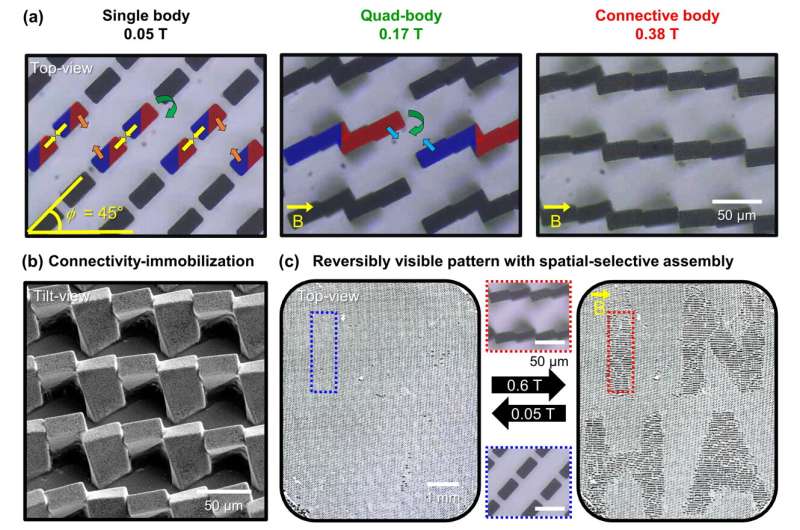

Previously, synchronized bending or twisting actuations of

micropillar arrays were demonstrated by programming the arrangement

of the magnetic particles and by employing anisotropic micropillar

geometry. In this case, magnetic particles are included in a

polymer matrix at low concentrations to avoid magnetic interference

and thereby achieve synchronized actuation. Researchers from Inha

University (Jeong Eun Park and Jeong Jae (JJ) Wie), Air Force

Research Laboratory (Augustine Urbas and Zahyun Ku), and Lawrence

Livermore National Laboratory (Sei Jin Park) recently reported an

opposite strategy to induce magnetic self-assembly of micropillar

arrays. Highly concentrated magnetic micropillars act as

micromagnets and collectively assemble with neighboring pillars

under an applied magnetic field. For facile actuation, flexible

rubber is utilized for pillar-base while relatively rigid and

magnetically responsive pillar-tops undergo the magnetic assembly.

As the pillar-base is magnetically inert and fixed to substrate,

self-assembly of periodically arranged micropillars can repeat

reversible and reproducible assembly and recovery by modulating the

external magnetic field.

Stepwise magnetic self-assembly of micropillar arrays with

long range order