Advances in nanotechnology require the development of

nanofabrication methods for a variety of available materials,

elements, and parameters. Existing methods do not possess specific

characteristics and general methods of versatile nanofabrication

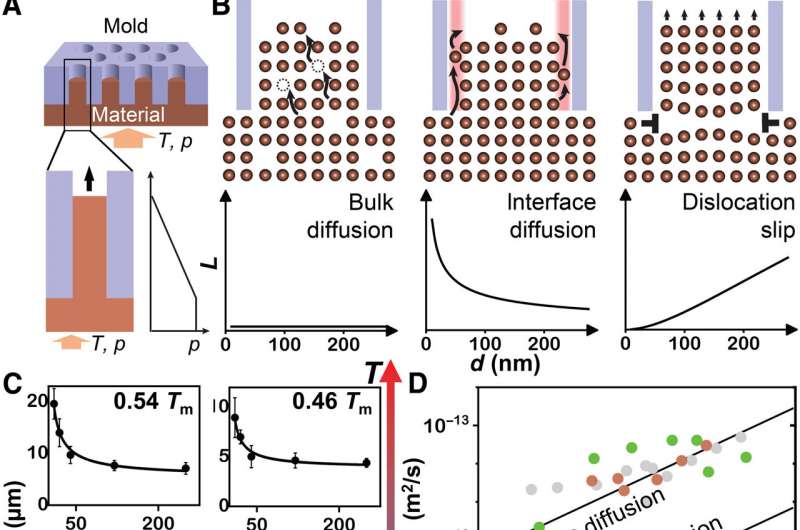

remain elusive. In a new report now published in Science Advances,

Naijia Liu, Guannan Liu and a team of scientists in mechanical

engineering and materials science at the Yale University and the

University of Connecticut in the U.S. described the underlying

mechanisms of thermomechanical nanomolding to reveal a highly

versatile nanofabrication approach. Based on the results, they

could regulate, combine and predict the ability to develop general

materials with material combinations and length scales. The

mechanistic origins of thermomechanical nanomolding and their

temperature-dependent transition provided a process to combine many

materials in nanostructures and provide any material in moldable

shapes at the nanoscale.