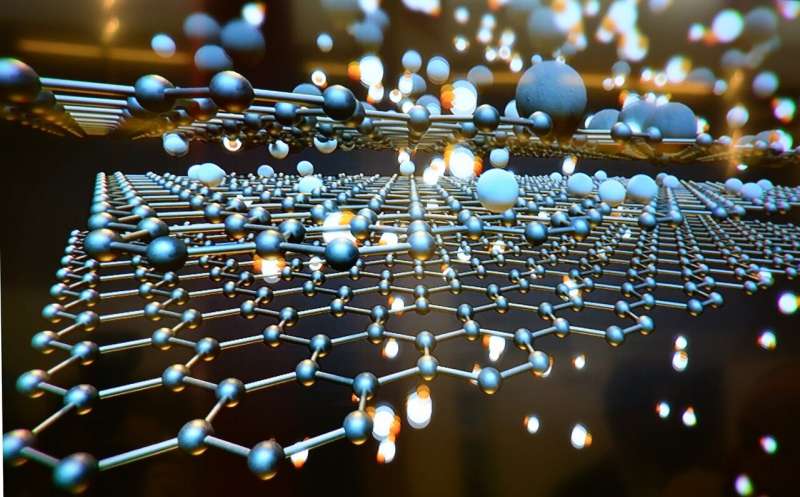

Vanderbilt engineers used a drop of rubbing alcohol,

an office laminator and creativity to develop scalable processes

for manufacturing single atom thin membranes. Their membranes

outperformed state-of-the-art commercial dialysis membranes and the

approach is fully compatible with roll-to-roll

manufacturing.

A drop of rubbing alcohol and office laminator provides a

manufacturability boost for nanomaterials